| Home |

| Deburring |

| Fastener Insertion |

| Graining |

| Polishing Machines |

| Oxide Film Removal |

| Lasers |

| Contact Us |

|

Evergreen Punching Machines

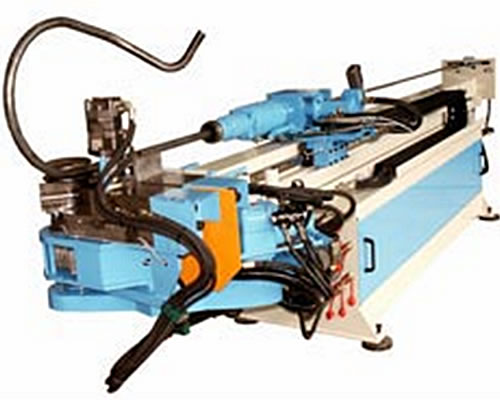

The S 60.5 is a fully automatic, electro-hydraulic

cold tube bending machine equipped with innovative spring-back compensation

technology and 5-axis CNC controls for

producing large or small bending radii in a single clamping. No matter what

the material, this machine

automatically calculates and adjusts for tube spring-back during the first bending

process and bends accurately the first time. The S 60.5

is capable of mandrel bending, ring bending, curve bending, 3D bending and coiling

with a single

bending head in a single clamping. The modular design allows the machine

to be expanded and enhanced for every customer at the time of purchase or at a later

date.

Modern Measuring Systems

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Wyvern Fabricating Solutions |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||