|

- Maximize your insertion productivity and quality with Haeger's

exclusive performance enhancing features.

- The WindowTouch with the Turret Insertion System enables

the insertion of up to four different fasteners in one handling, providing a productivity

boost of 40% or more.

- InsertionLogic software plus InsertionGraphics (Patent

Pending) helps to virtually eliminate costly quality issues.

Features & Benefits

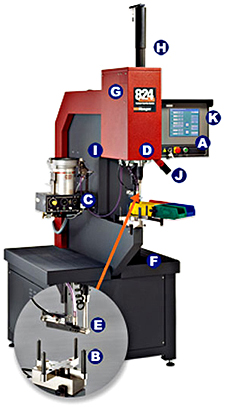

A. InsertionLogic Software + Insertion Graphics and Quality

Control Pack

- All NEW Version 9 w/ Optional Quality Control Pack includes

Networking Software Communication, Offline Programming and Digital Camera Package.

- The networking feature provides simple communication

between the WindowTouch and a PC or network. Create and store programs off-line and

call them up on multiple machines.

- The Offline Programming software allows creation of

programs on a PC, eliminating the need to stop the machine to create a program.

- InsertionGraphics provides a visual guide through

the

insertion process. Part images are displayed on the computer touch screen — each

fastener position on the part is displayed with a color-coded flashing dot. This

virtually eliminates the possibility of missing a fastener or inserting one in the

incorrect location.

- The new and improved Quality Assurance feature checks fastener

length and presence.

- Multiple types/sizes of fasteners are inserted in one

part handling.

- Touch Screen Control PC based, 12-inch full color touch

screen interface featuring the Microsoft® Windows XP operating system, solid state

memory, 640 x 480 resolution, 128MB RAM working memory, 512MB flash memory (storage),

Ethernet port and USB port.

- Languages

InsertionLogic software can be configured to operate in fourteen languages, providing

valuable customization for worldwide

use and operation

|

B. Turret Insertion System (TIS–2)

The Turret Insertion System (TIS) enables up to four different fasteners to be inserted

in one Part Handling. The NEW TIS-2 provides tool position feedback and positive

locking station to ensure the operator is in the correct tool station, and the tool

never moves during insertion. Tool position feedback helps eliminate missing fasteners

by preventing the operator from moving to the next fastener until all the current

fasteners are inserted. The positive locking feature provides 100% alignment of

the insertion tools ensuring consistent alignment for AutoFeeding.

|

C. MAS

The nine-inch Modular Autofeed System (MAS) comes complete with vacuum generator.

|

D. Operator Safety System

Haeger’s patented Safety System is effective at any point in the ram stroke irrespective

of the tooling length, requiring no set up by the operator; thus not affecting initial

machine set up time.

|

E. New Multi-Shuttle Tooling Platform for Nuts, Studs,

Standoffs

The NEW Multi-Shuttle Platform provides universal quick and easy tool change-over

between nuts, studs, and standoffs — enabling 2 minute total tool changes without

realignment. The Multi-Shuttle platform, available on the WindowTouch exclusively,

shares tooling modules with the OneTouch providing higher consistency, less training,

and broader use of tooling for both machines. Change over between Manual and Automatic

Tooling set up is faster and easier. (see page 12)

|

F. Fully Hydraulic System

The WindowTouch is extremely accurate and allows the operator to apply full tonnage

at any point in the stroke. Faster ram speed increases productivity, reduces part

cost and provides faster payback. The electronically controlled hydraulic system

assures the most repeatable force in the industry.

|

G. Low Energy Usage

The hydraulic system uses approximately 40% less energy than air or air over hydraulic

methods making it less expensive to operate.

|

H. Positive Stop

Ideal for insertions into thin gauge materials and other delicate insertion applications

where absolute repeatability is critical. The Positive Stop is a standard feature

and facilitates insertion in parts where pressures as low as 50lbs. may be needed.

|

I. Custom Tooling and Special Applications

Haeger provides an unmatched selection of standard tooling in both

inch and metric hardware, while Haeger's in-house capabilities provides solutions

to engineer and manufacture manual and automatic tooling for virtually any fastener.

|

J. Laser Part Locating Light

The NEW laser part locating light guides your insertion process with a “red cross

hair”

laser locator to show exactly where each fastener is inserted. The light provides

fast location and identification.

|

K. Digital Camera Interface

The Haeger supplied digital camera, which is part of the Quality Control Pack, provides the

ability to take part pictures at the machine and immediately import them into a part

program.

|